Vertical Laminar air flow (LAF) cabinet

Features:

Interior space made of high-quality 304 stainless steel.

External : made of high-quality 304 stainless steel.

Includes ultraviolet (UV) lights in work area Japanese Philips for

sterilization.

Swedish wire original.

Turkish electric socket.

LCD screen for controlling .

control 100% manufacture (chem tech)

Top air source with HEPA filter.( 99,999% Efficiency for Particles

≥0,3µm ( H14 class according to EN 1822))

two sources of electricity in the interior

Interior illumination (fluorescent lamp).

Applied with pre-filter and one HEPA filter.

Equipped with air fan with controlling the air speed.

Manual open – close door .

Turkish blower.

Vertical clean airflow directed downward onto the cabinet work zone

Replacable pre-filter for trapping large particles

Control panel for time, set-up and monitoring air velocity via sensors

Audible and visual alarm system for at least compromised airflow

Made in Egypt

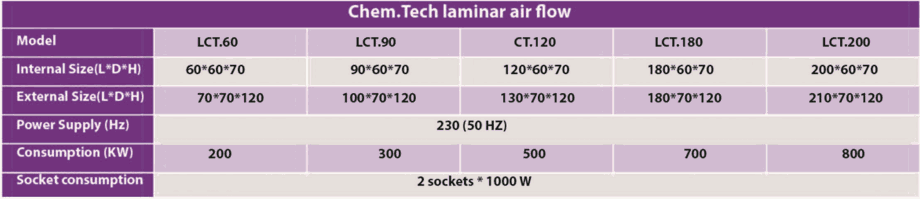

Specifications for Vertical Laminar air flow (LAF) cabinet

| Length | 120 cm or 150 cm or 180 cm |