Introduction:

At the heart of GMP lies the commitment to ensuring that medicinal and food products meet the quality standards necessary for their intended use.

As stated in GMP guidelines, Quality Management is a wide-ranging concept, which covers all matters, which individually or collectively influence the quality of a product. It is the sum total of the organized arrangements made with the objective of ensuring that medicinal products are of the quality required for their intended use. EU GMP - Eudralex - Ch1- 1.1

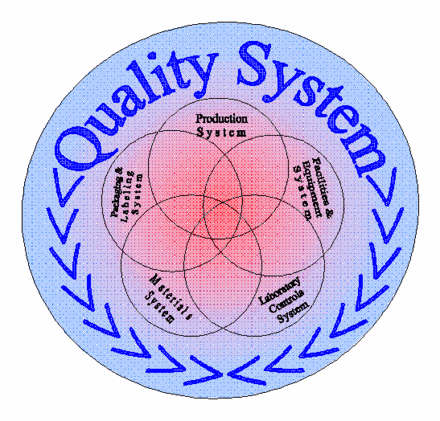

The Quality Systems Model: A Comprehensive Approach

Each manufacturer shall establish the appropriate responsibility, authority, and interrelation of all personnel who manage, perform, and assess work affecting quality, and provide the independence and authority necessary to perform these tasks. FDA 21 CFR 820- 20.b.1

The model is described according to four major factors:

· Management Responsibilities

· Resources

· Manufacturing Operations

· Evaluation Activities

FDA Guidance for Industry- Quality Systems Approach to Pharmaceutical CGMP Regulations- IV

Management Responsibilities: Leading the Way

Management holds the key to designing, implementing, and managing the quality system effectively. By providing:

1. Leadership

2. Structure the Organization

3. Build Your Quality System to Meet Requirements

4. Establish Policies, Objectives, and Plans

5. Review the System

FDA Guidance for Industry Quality Systems Approach to Pharmaceutical CGMP Regulations- IV.A

management sets the tone for quality assurance throughout the organization.

Resources: The Foundation of Quality Assurance

Appropriate allocation of resources is key to creating a robust quality system and complying with the CGMP regulations. FDA- Guidance for Industry- Quality Systems Approach to Pharmaceutical CGMP Regulations- IV.B

Each manufacturer shall provide adequate resources, including the assignment of trained personnel, for management, performance of work, and assessment activities, including internal quality audits, to meet the requirements of this part.

FDA 21 CFR 820 - 20.b.2

Manufacturing: Ensuring Process Consistency

Significant overlap exists between the elements of a quality system and the CGMP regulation requirements for manufacturing operations.

From designing and documenting products and processes to examining Inputs and Performing and Monitoring Operations finally addressing nonconformities, every step in the manufacturing process contributes to maintaining product quality.

FDA- Guidance for Industry- Quality Systems Approach to Pharmaceutical CGMP Regulations- IV.c

Evaluation Activities: Continuous Improvement

Quality systems call for continually monitoring trends and improving systems. This can be achieved by monitoring data and information, identifying and resolving problems, and anticipating and preventing problems.

Regular data analysis, internal audits, quality risk management, and corrective and preventive actions are integral to promoting continual improvement within the quality system. FDA Guidance for Industry Quality Systems Approach to Pharmaceutical CGMP Regulations- IV.D

Quality unit

Current industry practice generally divides the responsibilities of the quality control unit (QCU), as defined in the CGMP regulations, between quality control (QC) and quality assurance (QA) functions.

QC usually involves

(1) assessing the suitability of incoming components, containers, closures, labeling, in-process materials, and the finished products.

(2) evaluating the performance of the manufacturing process to ensure adherence to proper specifications and limits; and

(3) determining the acceptability of each batch for release.

QA primarily involves

(1) review and approval of all procedures related to production and maintenance,

(2) review of associated records, and

(3) auditing and performing/evaluating trend analyses.

FDA Guidance for Industry Quality Systems Approach to Pharmaceutical CGMP Regulations- III.F

Conclusion

Incorporating a comprehensive quality systems model into pharmaceutical and food manufacturing operations is essential for compliance with GMP regulations. By prioritizing quality assurance and fostering a culture of continuous improvement, these industries can consistently produce safe and effective products that meet regulatory standards.

References

1. EudraLex, Volume 4, Part 1 Chapter 1: Pharmaceutical Quality System

2. ICH

Topic Q

7a Good Manufacturing Practice for Active Pharmaceutical Ingredients

3. FDA- 21 CFR – Part 820 Quality System Regulation

4.WHO, TRS 986, Annex 2, WHO good manufacturing practices for pharmaceutical products: main principles

5. FDA, FDA Guidance for Industry Quality Systems Approach to Pharmaceutical

CGMP Regulations