Designed for uniform circulation of hot air in the drying chamber. Electrical/Steam. CGMP models with SS 316/304 Construction, Inside of the dryer.

Construction: EXTERNAL: 1.6MM THKINTERNAL:2MM THK MOC: CGMP

Surface Finish: Ruffed to 150 grit matt finish INTERNAL: Buffed to 220 grit mirror finish.

Inlet& Outlet: All dryers have a 5 micron pre-fiter at the inlet and a manually infinite adjustable damper at the outlet.

Doors: Doors are provided at the front and/or rear side of the dryer. Door lips are lined with silicon rubber gasket to prevent any leakages. Suitable locking is provided for the doors.

Air circulation: Air circulation is done by specially designed recirculation blowers inside the dryer. The blower capacity, static & design depends on the size and model of dryer.

Heating: Dryers are normally supplied with either electric heating system

TEMPERATURE CONTROL: Temperature control system is done by electronic digital temp controller fitted in the control panel. The temp control in the dryer is fully automatic.

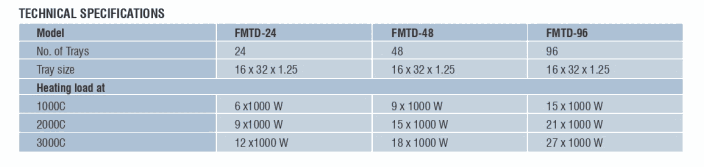

Trays: Trays are available in S.S. 304/316q. All trays are fully die pressed and with coved corners. Trays are buffed to mirror finish Trays are also available in aluminum/Polypropylene/ Frp/ M.S. galvanized as per clients requirements.

Control panel : Automatic Control panel is fitted on the side of the dryer, it consists of Starters, contactors, safety relays, ckt breakers, indicating lamps, push buttons, timers, controllers etc.